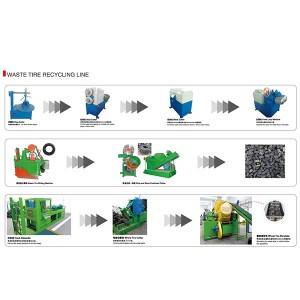

◐ Solution1:Traditional configuration

◐ Solution2:Economical configuration

◐ Solution3:Automatic configuration

◐ No.1 Quotation List

|

No. |

Name |

Model |

Unit price (US$) |

Quantity (Set) |

Amount (US$) |

Motor Power (KW) |

||

| Whole tyre Pre-processing :extract the steel Rim from tyre, and get <50x50mm rubber block | ||||||||

| 01 | Single Hook Debeader |

LSJ-1300 |

|

1 |

|

15 |

||

| 02 | Whole Tyre Cutter |

QDJ-1300 |

|

1 |

|

7.5 |

||

| 03 | Whole Tyre Shredder(with feed conveyor) |

ZPS-900 |

|

1 |

|

30×2+1.1+2.2=63.3 | ||

| Rubber granule processing: Crush the above block into 2-5mm rubber granules, at the same time, separate steel wire | ||||||||

| 04 | Rubber Cracker Mill |

XKP-710 |

|

1 |

|

250 |

||

| 05

|

Auxiliary Equipment |

Main Vibrating Screen |

MVS-11 |

1 |

|

11 |

26.5 |

|

|

Auxiliary Vibrating Screen |

AVS-4 |

4 |

||||||

|

5 Roll Magnetic Separator |

RMS-1.5 |

1.5 |

||||||

|

Water-cooled screw feeder |

RPF-3 |

3 |

||||||

|

Coarse Rubber Powder Return Belt |

PRB-1.5 |

1.5 |

||||||

|

PVC anti-tie steel wire conveyor belt |

WCB-4 |

4 |

||||||

|

Front and rear lifting assembly of gantry frame |

AGF-1 |

|

||||||

|

2-roll magnetic separator |

RMS-2 |

1.5 |

||||||

| Total |

5 |

362.3KW |

||||||

| Note:1. These all machines prices are based on FOB Qingdao. | ||||||||

◐ No.2 Business Terms

| Payment terms | 1. 30% T/T of total contract value to be paid in advance.

2. The balance 70% to be paid when all the machines get ready for delivery. |

| Power supply | As per the buyer’s requirement( it should be confirmed in the contract ) |

| Terms of Delivery | Delivery Time:60 days after receipt of 30% down payment |

| If required, the seller will arrange 1~2 professional technicians to guide installation and debugging the machines at buyer’s plant, visa round trip and tickets, hotel cost, food are buyer cost. The exact cost will be discussed further. | |

| Warranty | 18 months since the normal working in the buyers' factory. |

| Validity of

the Quotation |

30 days since the offer date |

◐ No.3 General Introduction for Each Machine

1.Single Hook Debeader LSJ-1300

Use: Pulling out the wire loops from the mouth of waste tires.

Structure Features:

The blade of cutter is made of alloy welding and the surface is hard wear-resisting.

On safety factor, this machine have protective frame, which can effectively guarantee safety in the process of pulling out wire loop.

Motor and reducer, and as a whole, the structure is compact.

The machine occupies the whole floor, convenient installation.

Technical Parameters:

| Model | LSJ-1300 |

| Pulling Force | 5T |

| Motor Power | 15KW |

| Max. Tire range | 1300mm |

| Overall Dimension (L×W×H) | 1900×1055×1355 (mm) |

| Weight | 2.5T |

Reference Photo

(wires in the tyre mouth) |

|

2. Whole Tire Cutter QDJ-1300

Use:

Cut the waste tires blocks into several parts and will be more convenient for tire shredder machine shredding.

The tire blocks cutting machine is made up of motor, hydraulic system, oil cylinder, one pair of blade, frame and rotating body etc.

Technical Parameters

| Adapt tire | ≦1300mm |

| Motor power | 7.5kw |

| Dimension (L×W×H) | 2080×1000×2130 (mm) |

| Weight | 1.8T |

Reference Photo

(tyres cut in pieces)

|

|

3. Whole Tire Shredder ZPS-900

Use:

At the general temperature, the large tire blocks can be shredded directly into 50*50mm tire blocks.

Technical Parameters:

4. Rubber Cracker Mill XKP-710

Use: Mainly used for crushing large rubber blocks into 2-5mm rubber granules.

Structural Features:

Our crushers are designed humanized with nice operating platforms; all the wires will be connected well from controlling system to motor.

When using the machine, the customers just need to connect directly to the power.

Technical Parameters:

5. Rubber Cracker Mill Auxiliary Equipments

Function: Separate the wire, Screening the qualified rubber granules

1) Main Vibrating Screen: Length 8m, Width 1.15m. Stainless steel screen.

2) Auxiliary Vibrating Screen: Length 4m, Width 1m.

3) 5 Roll Magnetic Separator: Power 1.5kw

4) Water-cooled screw feeder: Lenghth 3m

5) Coarse Rubber Powder Return Belt: Lenghth 2m

6) PVC anti-tie steel wire conveyor belt: Length 8.5m, Width 0.8m.

7) Front and rear lifting assembly of gantry frame: Screw rod hoisting 1 set

8) 2-roll magnetic separator: Technical specification of vulcanized rubber powder with metal content less than or equal to GBT 19208-2008

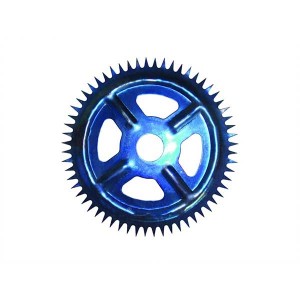

|

(Separated small steel wires from rubber granules) |

|