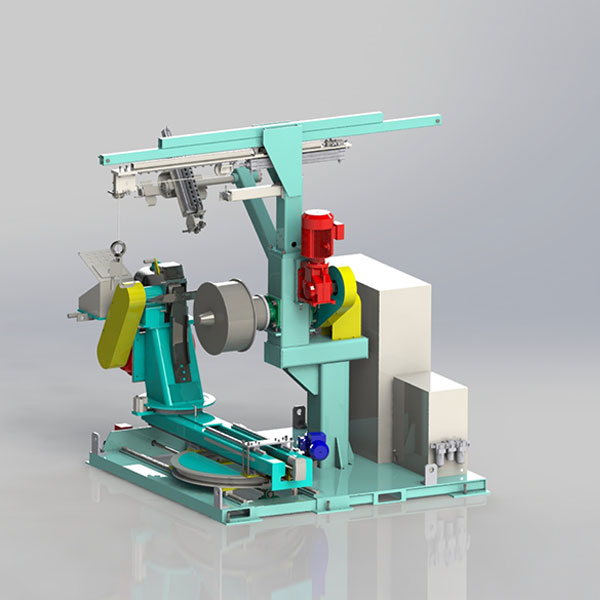

China Wholesale Wire Rasp Suppliers - Semi-Automatic Buffing Machine – Bestyre Detail:

◐ Equipment Features

1.The equipment is with accurate controlling process and high level mechanic designing, which is simple to operate and runs stably.

2.Equipped with water cooling rasp and automatic blades renew device. The blades can be used with 80% more working endu rance.

3.The buffing quality can be proved more stable in accordance ofthe working of automatic belt measuring device.

4.Casing drove by expandable rim, in order to ensure dynamic performance ofthe retread tires.

Buffing station requirements

◐ Suggested configuration/tools

1. Exhaust and dust removal system

2. Taper and needle-nosed pliers (cut the leaking wire)

3. Tire marking chalk (mark the location of the wound, tread width, etc.)

4. Lubricating agent of expansion wheel (apply regularly)

5. Tire parameter table (input PC configuration table in advance, and call it out directly when polishing)

6. Tread base measuring ruler/pattern depth meter/flexible tape measure (can be used for phased detection)

7. RMA standard grinding roughness template (used to judge the wear of grinding tool head)

8. Goggles with side protection

9.Safety shoes

◐ Process conditions

1.Compressed air pressure: 5 ~ 8kg/cm

2.Tire inflation pressure: 1.5kg /cm2.

◐ Buffing position quality standard

◐ Safet

1.Before buffing, eliminate the visible foreign matter, including stone, nails, screws, etc.

2.inflatable no more than 15 psi (1.5 Kg/cm2).

3. labor protection glasses

4. not allowed to wear gloves and wear comfortable clothes

5.long hair must be bandaged up

Please refer to the manual grinding machine equipment, understand any security problems.

◐ Production objectives

1. Safe production;

2. process standardization, efficiency maximization, production of fine Retreading tires.

Product detail pictures:

Related Product Guide:

To fulfill the customers' over-expected fulfillment , we have now our solid staff to deliver our greatest general assistance which includes internet marketing, product sales, creating, manufacturing, excellent controlling, packing, warehousing and logistics for China Wholesale Wire Rasp Suppliers - Semi-Automatic Buffing Machine – Bestyre, The product will supply to all over the world, such as: Mauritania, Amsterdam, Accra, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

-

China Wholesale Tire Tread Rubber Manufacturers...

-

China Wholesale Laser Light Line Marker Supplie...

-

China Wholesale Scanner Tpms Suppliers - Otr A...

-

China Wholesale Dust Removal Machine Rental Man...

-

Newly Arrival Retread Skid Steer Tires - Ring-...

-

China Wholesale Rubber Cement Waterproof Factor...