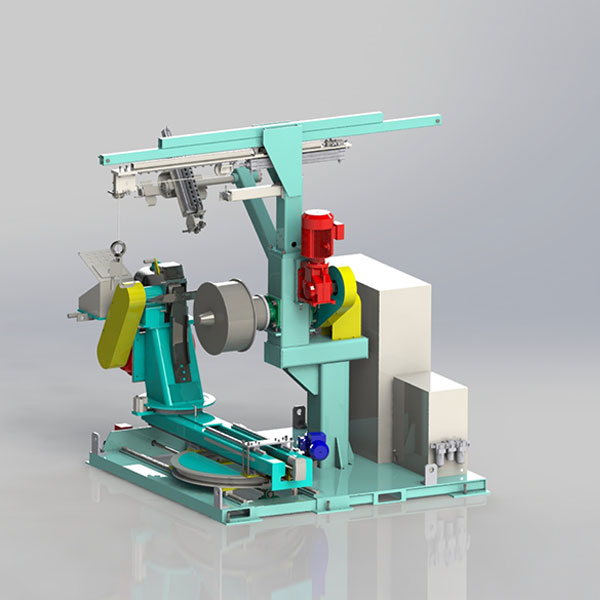

China Wholesale Rubber Cement On Glass Factory - Semi-Automatic Buffing Machine – Bestyre Detail:

◐ Equipment Features

1.The equipment is with accurate controlling process and high level mechanic designing, which is simple to operate and runs stably.

2.Equipped with water cooling rasp and automatic blades renew device. The blades can be used with 80% more working endu rance.

3.The buffing quality can be proved more stable in accordance ofthe working of automatic belt measuring device.

4.Casing drove by expandable rim, in order to ensure dynamic performance ofthe retread tires.

Buffing station requirements

◐ Suggested configuration/tools

1. Exhaust and dust removal system

2. Taper and needle-nosed pliers (cut the leaking wire)

3. Tire marking chalk (mark the location of the wound, tread width, etc.)

4. Lubricating agent of expansion wheel (apply regularly)

5. Tire parameter table (input PC configuration table in advance, and call it out directly when polishing)

6. Tread base measuring ruler/pattern depth meter/flexible tape measure (can be used for phased detection)

7. RMA standard grinding roughness template (used to judge the wear of grinding tool head)

8. Goggles with side protection

9.Safety shoes

◐ Process conditions

1.Compressed air pressure: 5 ~ 8kg/cm

2.Tire inflation pressure: 1.5kg /cm2.

◐ Buffing position quality standard

◐ Safet

1.Before buffing, eliminate the visible foreign matter, including stone, nails, screws, etc.

2.inflatable no more than 15 psi (1.5 Kg/cm2).

3. labor protection glasses

4. not allowed to wear gloves and wear comfortable clothes

5.long hair must be bandaged up

Please refer to the manual grinding machine equipment, understand any security problems.

◐ Production objectives

1. Safe production;

2. process standardization, efficiency maximization, production of fine Retreading tires.

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for China Wholesale Rubber Cement On Glass Factory - Semi-Automatic Buffing Machine – Bestyre, The product will supply to all over the world, such as: Argentina, Bangladesh, Casablanca, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

-

China Wholesale Retread Snow Tires Suppliers -...

-

China Wholesale Laser Wedding Card Making Machi...

-

China Wholesale Pp Sutli Making Line Factories ...

-

China Wholesale Mehta Laser Machine Factories -...

-

OEM Customized Tpms Valve Stem Caps - Automati...

-

China Wholesale Tyre Pressure Valve Factories -...