Top Quality Cushion Gum - Automatic Extruding & Enwinding Machine – Bestyre Detail:

◐ Equipment structure and working principle

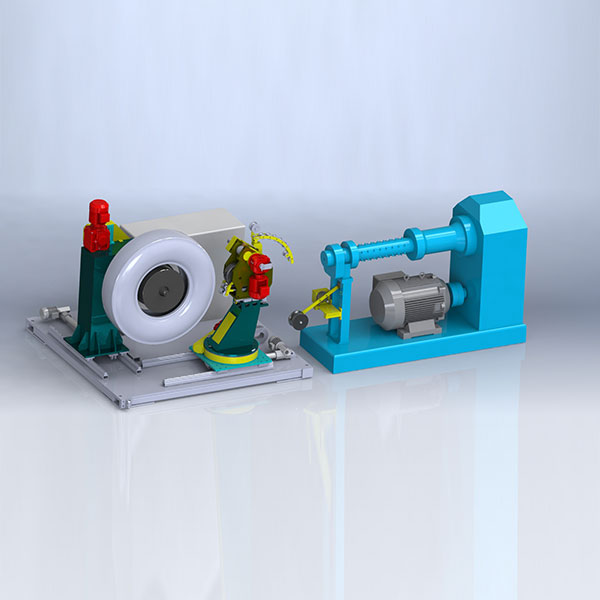

Ftc-1422 truck tire winding machine consists of five parts, as shown in the figure

1 winding head 2 winding base 3 main engine 4 base 5 material storage device

1.1 winding head

1) function: the rubber strip extruded by the extruder is rolled into the shape required by the process to ensure the consistency and uniformity of the rubber strip shape. At the same time, the rubber strip attached to the tire surface is pressed to ensure its firm bond with the tire body and remove the bubbles at the joint, which is very important for the quality of winding.

2) structure: guide device, rolling device, roller, side roller, guide rail, etc

1 guide device 2 calender device 3 roller 4 side roller 5 guide rail

1.2 winding base

1) function: make the winding head move back and forth, cooperate with the main machine to do tread copying movement, and can rotate to make the winding head perpendicular to the bonding surface.

2) mechanism composition: winding base, rotating device, feed device, etc

1 winding base 2 rotating device 3 feeding device

1.3 the host

1) function: make the tires move from side to side, cooperate with the winding base to make tread copying movement, and inflate the tires.

2) mechanism composition: driving device, expansion drum, column, translation device, etc

1 driving device 2 expansion drum 3 column 4 translation device

◐ Technical parameters

2.1 main performance

· type of tires: truck tires

· applicable rim: 16″~24.5″

· minimum tire diameter: 700 mm

· maximum tire diameter: 1,400mm

· minimum tire surface width: 150mm

· maximum tire surface width: 500mm

Production capacity: 90 mm Ø extruder (wrapped around a 11.00 R20 tire about 4 minutes, tread compound quality 13 kg)

2.2 main parameters

· wheel rotating motor power: 1.5kw

·xy mobile motor power: 0.55kw

· rotary motor power: 1.5kw

· rolling motor power: 1.1kw

· ambient temperature: 5 ~ 40℃

· compressed air:

Air quality: dry and clean

Air pressure: ≥ 0.8mpag)

2.3 size and weight

Machine floor area: 6000×3000 mm

Main engine height: 2000 mm

Machine weight: 2000kg

Product detail pictures:

Related Product Guide:

We keep on with the theory of "quality first, provider initially, constant improvement and innovation to meet the customers" with the management and "zero defect, zero complaints" as the standard objective. To great our company, we deliver the merchandise using the fantastic excellent at the reasonable price for Top Quality Cushion Gum - Automatic Extruding & Enwinding Machine – Bestyre, The product will supply to all over the world, such as: South Africa, Los Angeles, Sweden, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

-

China Wholesale 4×4 Tyre Pressure Monitori...

-

China Wholesale Green Laser Marker Manufacturer...

-

Competitive Price for Laser Wedding Card Making...

-

China Wholesale Retread All Terrain Tires Facto...

-

China Wholesale Laser Trimming Machine Factorie...

-

China Wholesale Tire Pressure Monitor Valve Ste...