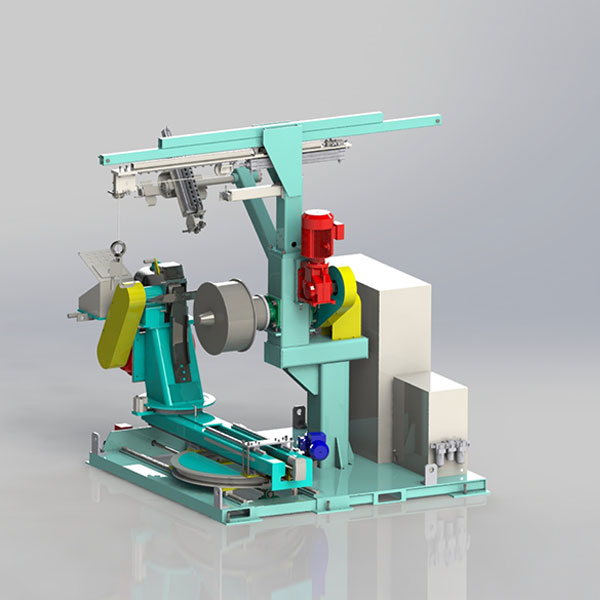

China Wholesale Rubber Cement On Glass Factory - Semi-Automatic Buffing Machine – Bestyre Detail:

◐ Equipment Features

1.The equipment is with accurate controlling process and high level mechanic designing, which is simple to operate and runs stably.

2.Equipped with water cooling rasp and automatic blades renew device. The blades can be used with 80% more working endu rance.

3.The buffing quality can be proved more stable in accordance ofthe working of automatic belt measuring device.

4.Casing drove by expandable rim, in order to ensure dynamic performance ofthe retread tires.

Buffing station requirements

◐ Suggested configuration/tools

1. Exhaust and dust removal system

2. Taper and needle-nosed pliers (cut the leaking wire)

3. Tire marking chalk (mark the location of the wound, tread width, etc.)

4. Lubricating agent of expansion wheel (apply regularly)

5. Tire parameter table (input PC configuration table in advance, and call it out directly when polishing)

6. Tread base measuring ruler/pattern depth meter/flexible tape measure (can be used for phased detection)

7. RMA standard grinding roughness template (used to judge the wear of grinding tool head)

8. Goggles with side protection

9.Safety shoes

◐ Process conditions

1.Compressed air pressure: 5 ~ 8kg/cm

2.Tire inflation pressure: 1.5kg /cm2.

◐ Buffing position quality standard

◐ Safet

1.Before buffing, eliminate the visible foreign matter, including stone, nails, screws, etc.

2.inflatable no more than 15 psi (1.5 Kg/cm2).

3. labor protection glasses

4. not allowed to wear gloves and wear comfortable clothes

5.long hair must be bandaged up

Please refer to the manual grinding machine equipment, understand any security problems.

◐ Production objectives

1. Safe production;

2. process standardization, efficiency maximization, production of fine Retreading tires.

Product detail pictures:

Related Product Guide:

The corporate keeps towards the operation concept "scientific administration, superior quality and performance primacy, client supreme for China Wholesale Rubber Cement On Glass Factory - Semi-Automatic Buffing Machine – Bestyre, The product will supply to all over the world, such as: Cyprus, New Zealand, Austria, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

-

High Quality Rubber Floor Tile Making Machine -...

-

China Wholesale Maker Laser Cutter Factories -...

-

China Wholesale Tire Retreading Air Tools Manuf...

-

China Wholesale Lasermark Rotary Laser Factory ...

-

PriceList for Car Dust Debre Remover Machine -...

-

China Wholesale Wireless Tire Pressure Monitori...