Best quality Tire Retreading Curing Chamber - Automatic Extruding & Enwinding Machine – Bestyre Detail:

◐ Equipment structure and working principle

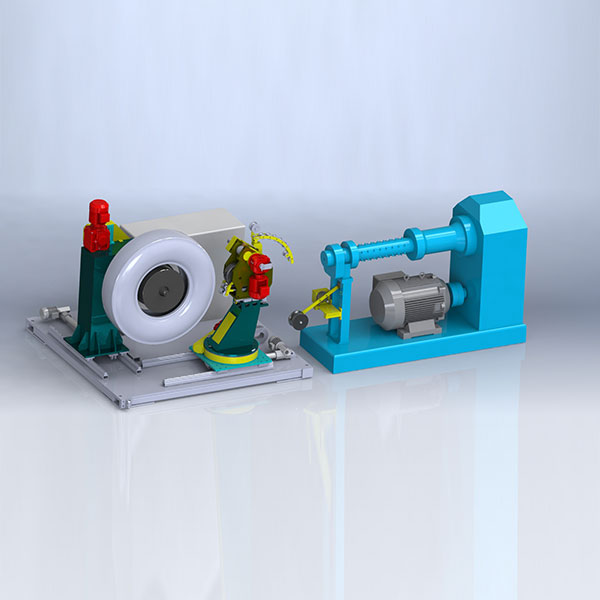

Ftc-1422 truck tire winding machine consists of five parts, as shown in the figure

1 winding head 2 winding base 3 main engine 4 base 5 material storage device

1.1 winding head

1) function: the rubber strip extruded by the extruder is rolled into the shape required by the process to ensure the consistency and uniformity of the rubber strip shape. At the same time, the rubber strip attached to the tire surface is pressed to ensure its firm bond with the tire body and remove the bubbles at the joint, which is very important for the quality of winding.

2) structure: guide device, rolling device, roller, side roller, guide rail, etc

1 guide device 2 calender device 3 roller 4 side roller 5 guide rail

1.2 winding base

1) function: make the winding head move back and forth, cooperate with the main machine to do tread copying movement, and can rotate to make the winding head perpendicular to the bonding surface.

2) mechanism composition: winding base, rotating device, feed device, etc

1 winding base 2 rotating device 3 feeding device

1.3 the host

1) function: make the tires move from side to side, cooperate with the winding base to make tread copying movement, and inflate the tires.

2) mechanism composition: driving device, expansion drum, column, translation device, etc

1 driving device 2 expansion drum 3 column 4 translation device

◐ Technical parameters

2.1 main performance

· type of tires: truck tires

· applicable rim: 16″~24.5″

· minimum tire diameter: 700 mm

· maximum tire diameter: 1,400mm

· minimum tire surface width: 150mm

· maximum tire surface width: 500mm

Production capacity: 90 mm Ø extruder (wrapped around a 11.00 R20 tire about 4 minutes, tread compound quality 13 kg)

2.2 main parameters

· wheel rotating motor power: 1.5kw

·xy mobile motor power: 0.55kw

· rotary motor power: 1.5kw

· rolling motor power: 1.1kw

· ambient temperature: 5 ~ 40℃

· compressed air:

Air quality: dry and clean

Air pressure: ≥ 0.8mpag)

2.3 size and weight

Machine floor area: 6000×3000 mm

Main engine height: 2000 mm

Machine weight: 2000kg

Product detail pictures:

Related Product Guide:

Quality First,and Customer Supreme is our guideline to provide the best service to our customers.Nowadays, we are trying our best to become one of the best exporters in our field to meet customers more need for Best quality Tire Retreading Curing Chamber - Automatic Extruding & Enwinding Machine – Bestyre, The product will supply to all over the world, such as: Peru, USA, Italy, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

-

Chinese Professional Rubber Tile Production Lin...

-

China Wholesale Tpms Caps Manufacturers - Auto...

-

China Wholesale Laser Milling Machine Manufactu...

-

Factory Supply Axon Tpms - 6 Tire Intelligent ...

-

China Wholesale Plastic Monofilament Rope Makin...

-

China Wholesale Retreading Tyres Cost Factory -...